Lab Grown diamonds have the same physical, chemical, and optical properties as Earth-mined diamonds.

Both are durable and beautiful, with the same sparkling light performance as each other. Where they differ is only in their formation process.

What is a Lab Grown Diamond?

Lab grown diamonds (also referred to as lab created, man-made, or synthetic diamonds), are diamonds that have been grown in a highly controlled laboratory environment. The process replicates the conditions under which diamonds naturally develop in the Earth's mantle, and starts with a small piece of diamond as a seed. Just like Earth mined diamonds, lab grown diamonds consist of pur carbon, and they exhibit the same crystalline structure. Becuase they consist of the same material, lab grown diamonds exhibit the same durability, refraction, and sparkle as a Earth mined diamonds.

Why Should I Choose a Lab Diamond?

Brilliance

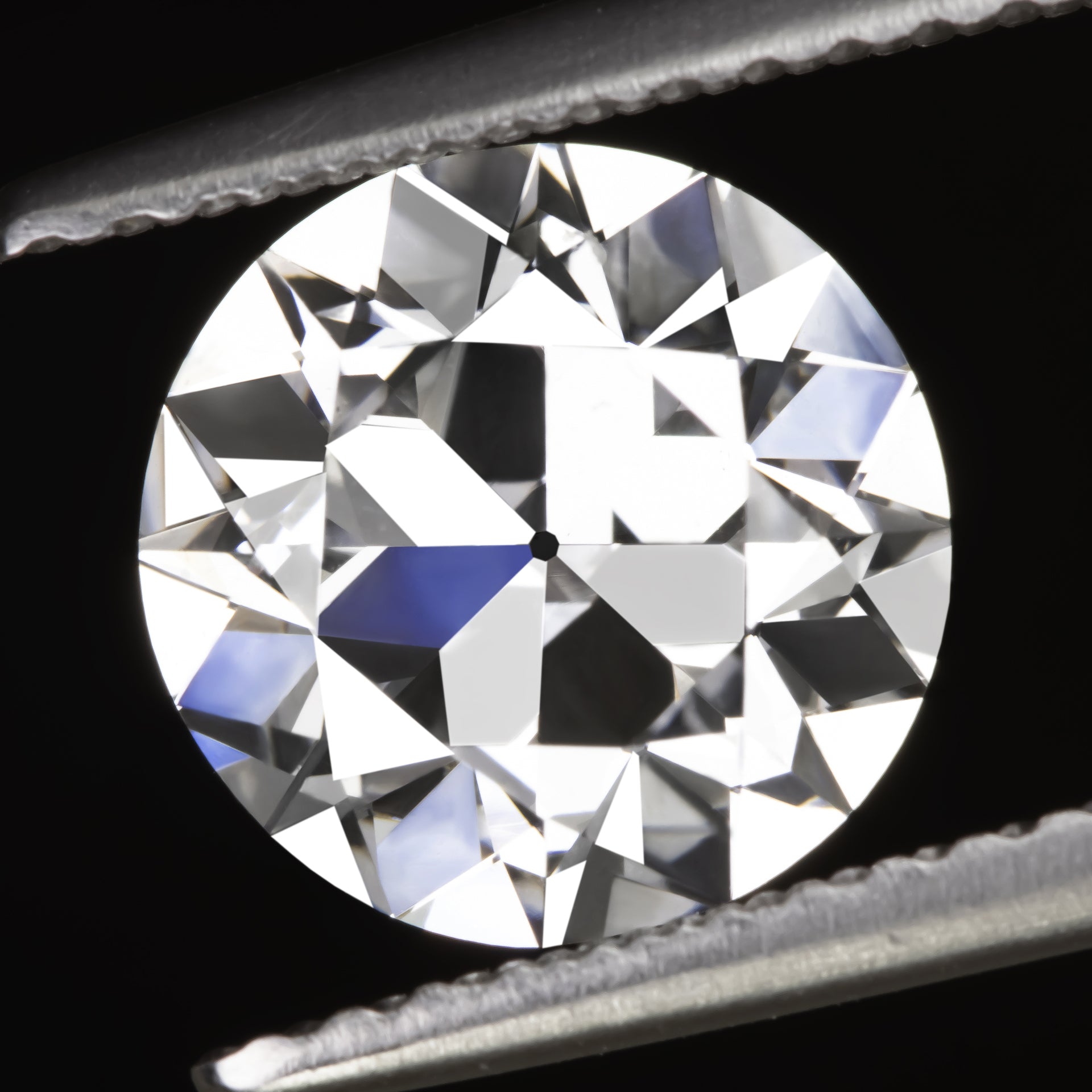

Lab grown diamonds offer the same optical properties as Earth mined diamonds. They have fantastic sparkle and fire!

Durability

Lab grown diamonds offer the same durability and longevity as an Earth mined diamond. They hold up very well to everyday wear.

Value

Lab grown diamonds are more cost-effective than Earth mined diamonds. You can maximize the size and quality of your diamond while still sticking to your budget.

Compare how lab grown and mined diamonds are formed

Earth Mined Diamonds

Diamonds that occur naturally within the Earth are forged under the crushing pressure of 90-125 miles below the surface of the Earth and the incredible heat of the Earth’s mantle. Some time long in the past, especially violent and deeply rooted volcanic eruptions, called Kimberlite eruptions, carried the rough diamond material from the upper mantle closer to the surface of the Earth. These Kimberlite eruptions had to happen very quickly to lock the diamond structure into place, otherwise the material would have had time to cool and turned to graphite instead. These eruptions happened long ago in Earth’s history, likely during a period when the Earth was hotter which is how the eruptions could be more deeply rooted than volcanic eruptions that have occurred in more recent times.Lab Grown Diamonds

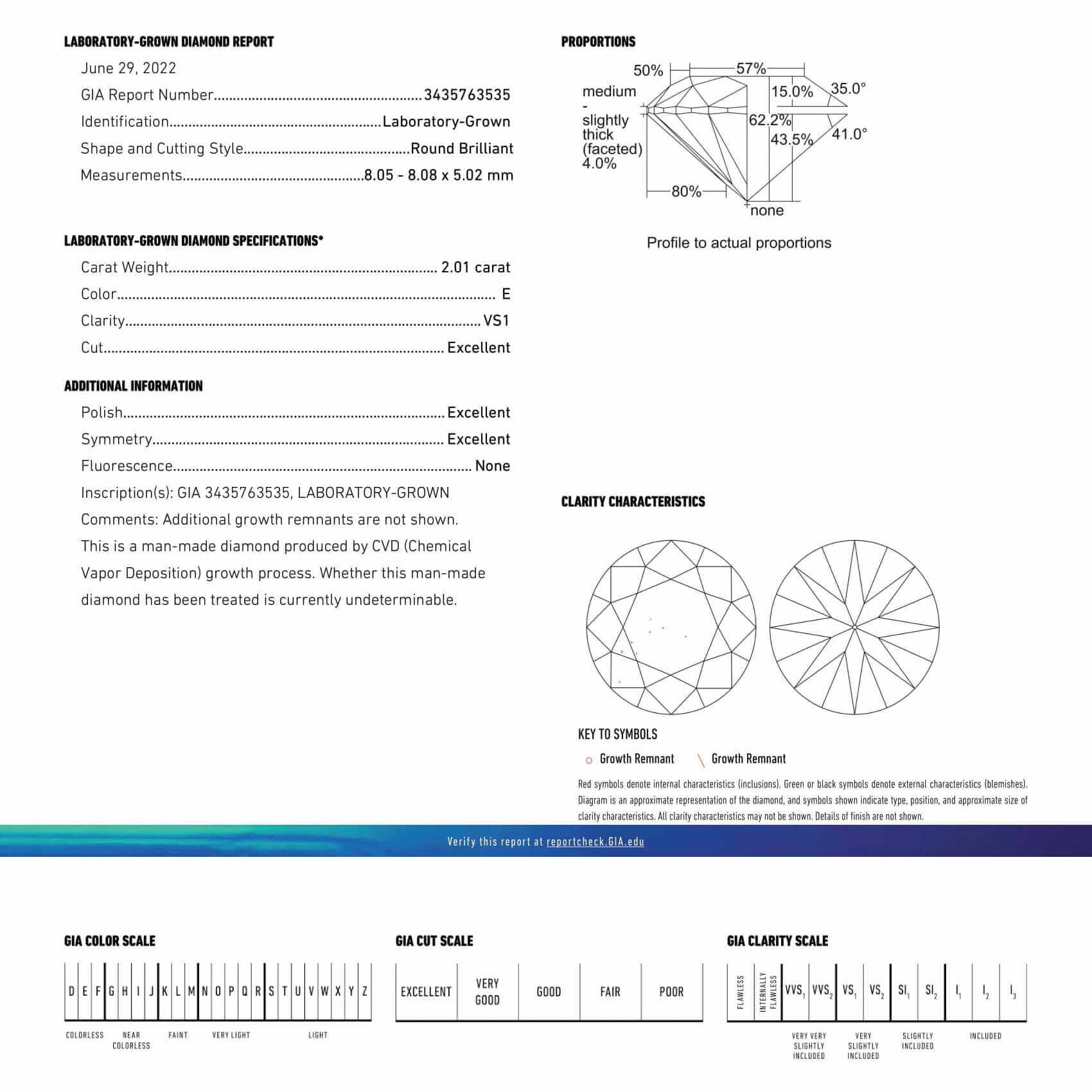

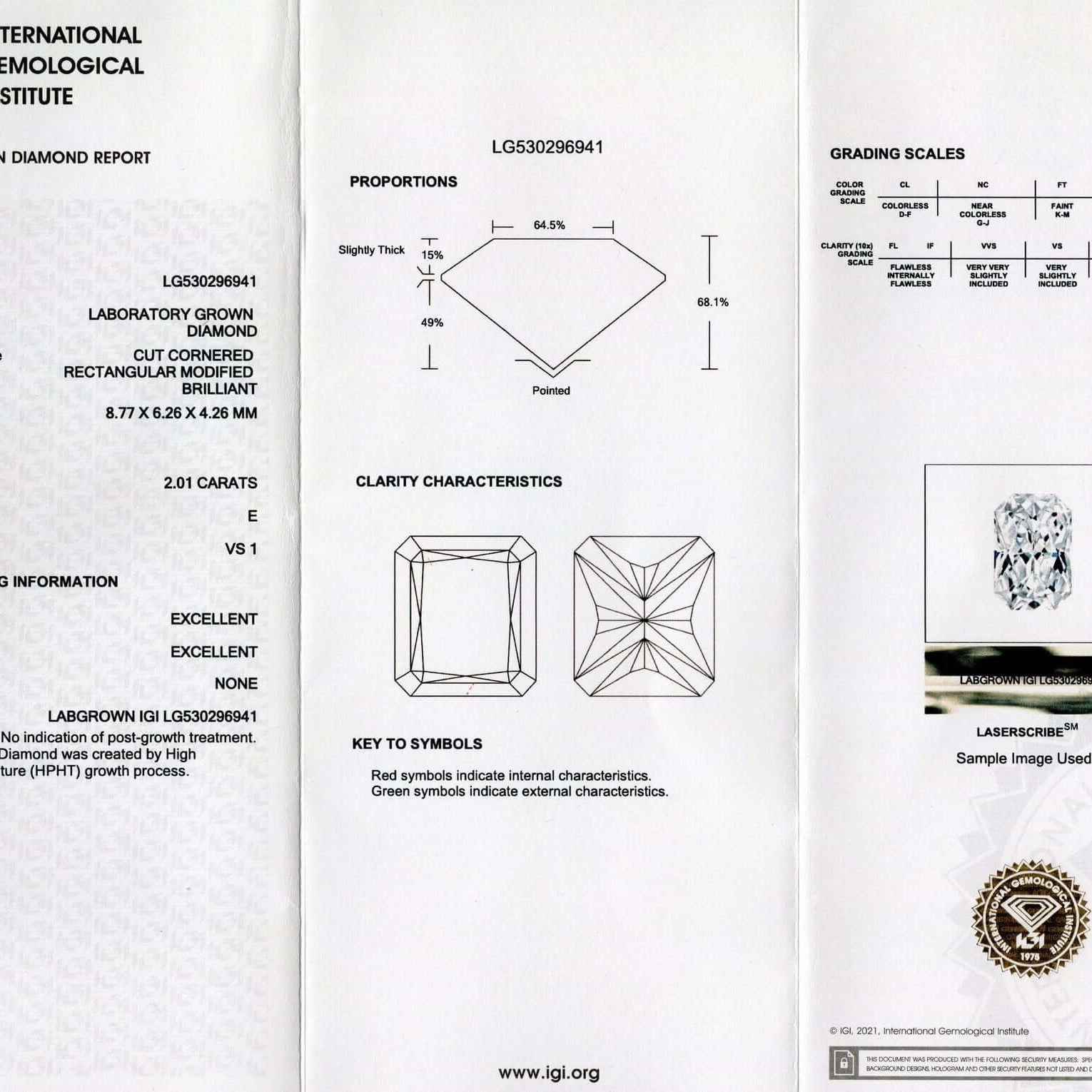

High Pressure High Temperature (HPHT)

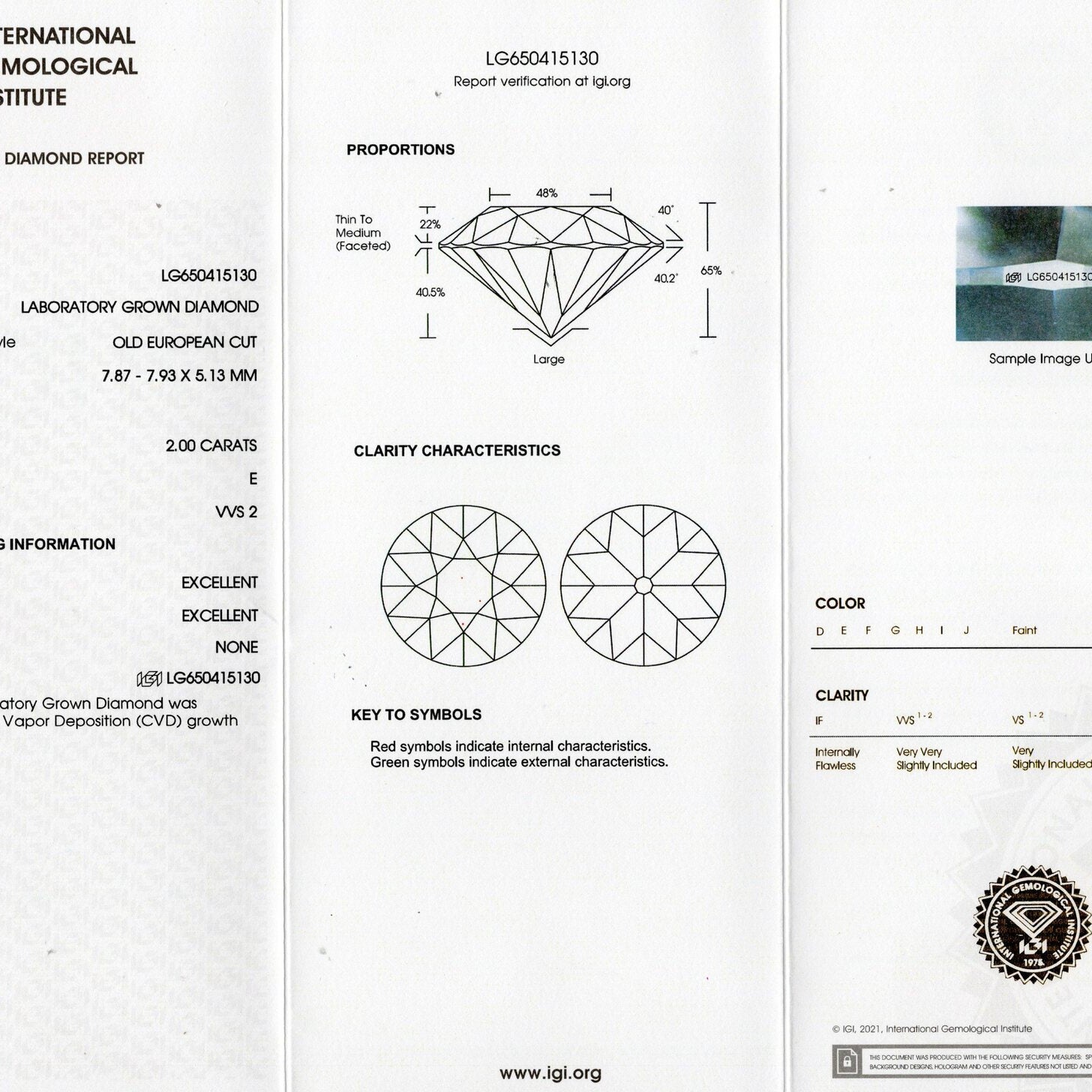

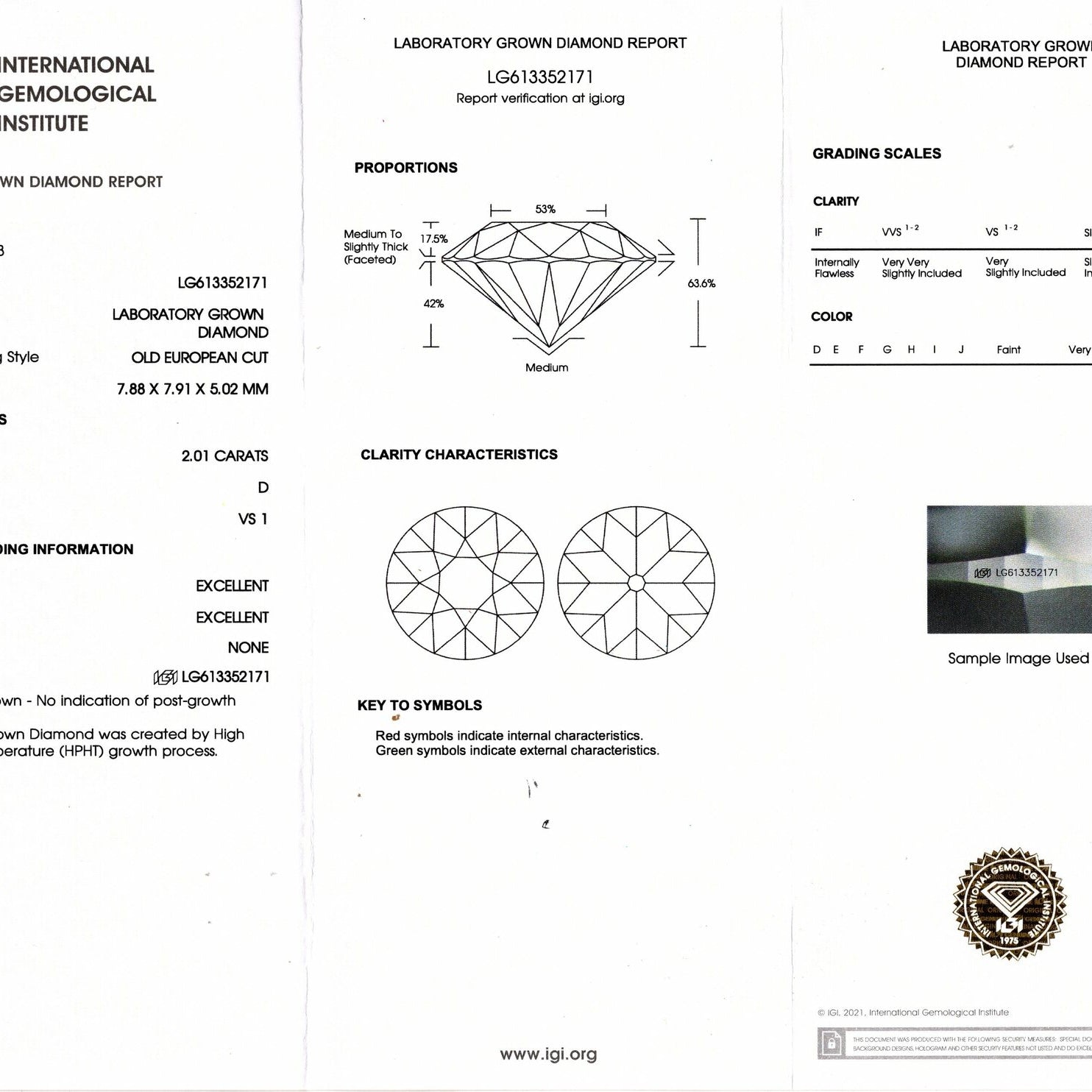

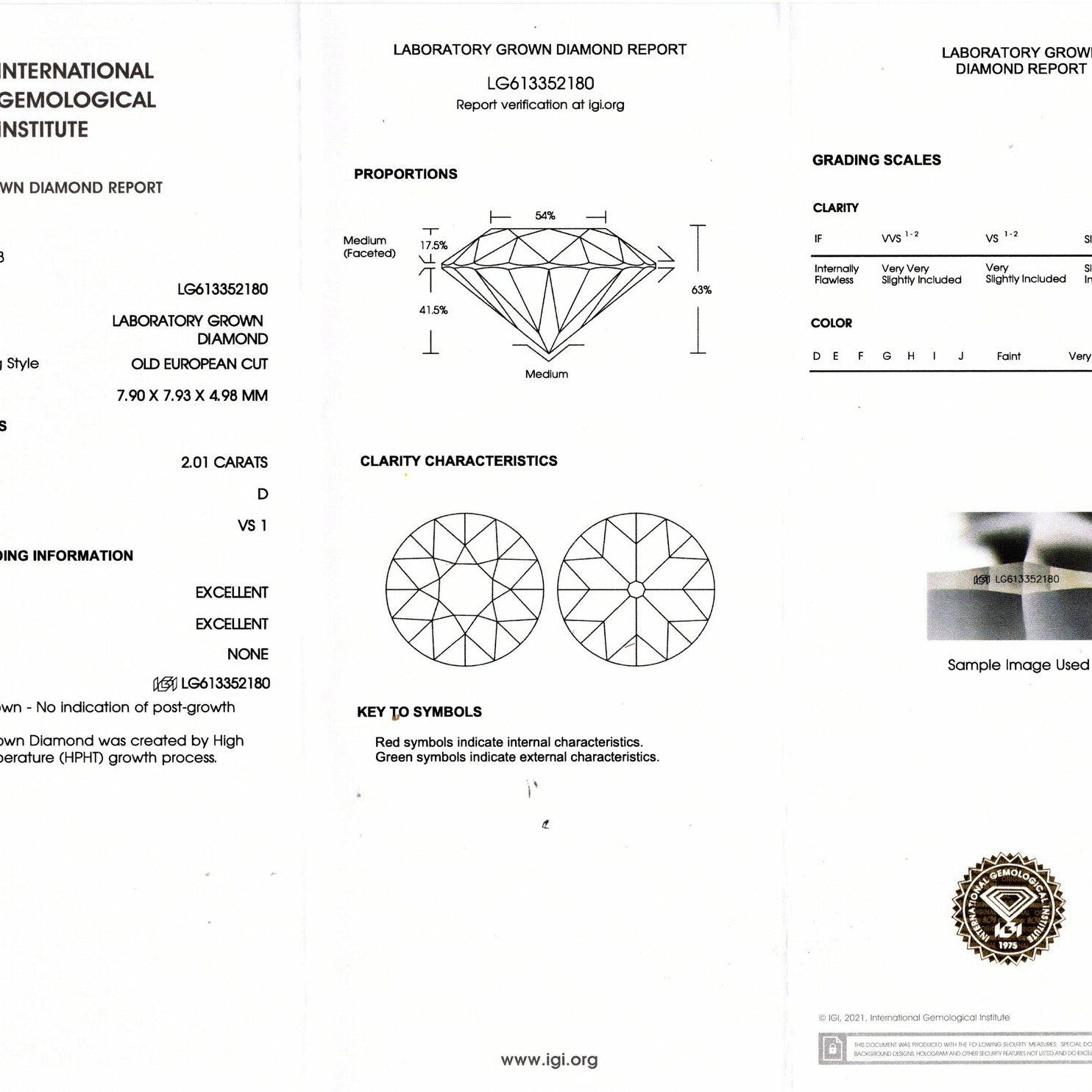

High Pressure High Temperature (HPHT) treatment is a process of growing diamonds in a laboratory that has been around since the 1950s. Initially the diamonds created in this way were used for industrial purposes, but in recent decades the ability to create very high quality diamonds has introduced this manufacturing method for use in the jewelry industry. The HPHT process is where the diamond seed is placed amongst pure graphite carbon in a controlled chamber. It is then exposed to temperatures of at least 1,500C and pressurized to approximately 1.5 million pounds per square inch. This process imitates how diamonds occur in nature, but at a much faster rate. Under the intense heat and pressure, the graphite carbon melts and interacts with the initial diamond seed to create a larger diamond crystal. Instead of taking 1-3 billion years to form, HPHT lab created diamonds can be formed within a couple of weeks!Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition (CVD) process is a more recently adopted method of growing diamond in a lab setting. This treatment also starts with a diamond seed in a controlled chamber. The chamber is then filled with a carbon-rich gas and heated to approximately 800C. Within the chamber, the gas ionizes - breaking down into pure carbon. These pure carbon molecules begin bonding to the diamond seed, growing the diamond atom by atom. The crystallization process continues until a full formed rough diamond is produced. This highly specialized, efficient process can create a diamond in less than a month!Making high quality diamond material more accessible.

The technology and techniques have improved during recent decades to create diamond minerals both at high scale and high quality. Today, the end customer can access an exquisitely high caliber diamond at a lower price point compared with Earth-mined diamonds of the same grading and size.

With the ability to control the conditions of formation, the production process ensures purer rough diamonds. In the controlled setting of the diamond growing chamber, the climate of the formation process has been manipulated so that anything which enters the chamber is intentionally there. Gasses which are present in the formation of natural diamonds over billions of years within the Earth will affect the look of the rough diamond crystal. The presence of nitrogen, for example, will have an impact on the color of a diamond during its formation process. If nitrogen has not intentionally been introduced in the lab creation process to create a fancy color diamond, then the likelihood of the diamond being within the most desirable ranges of colorless grades is far more possible.

Since the qualities of earth-mined diamonds are graded on their lack of naturally-occuring impurities (in color and clarity), the ability to control all the elements and circumstances of diamond formation creates a mineral with high color and clarity.

Now that more of this high quality material is available and worthy for precision cutting, there is a great emphasis on getting the most ideally cut diamond.

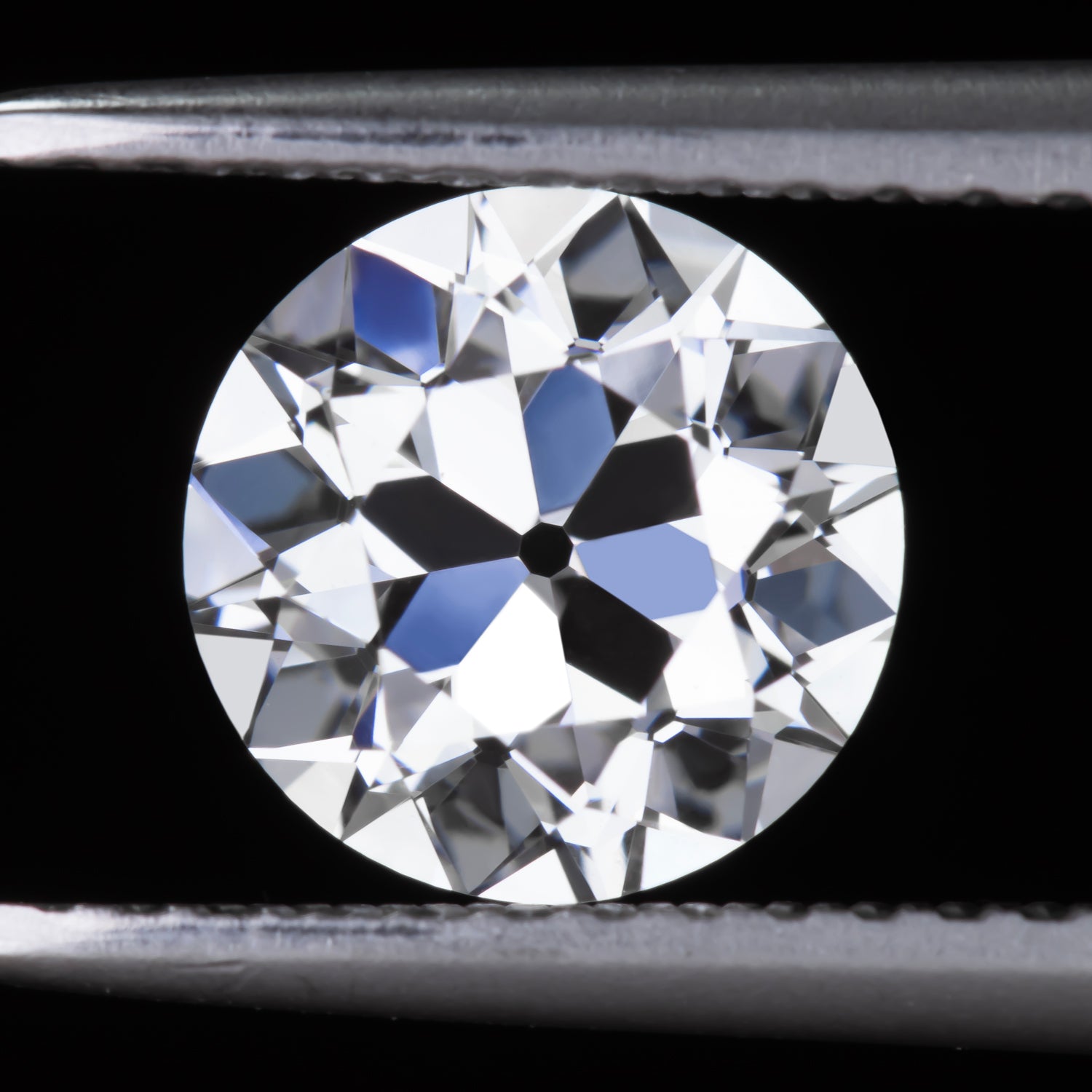

Exquisite Cutting

Now that more of this high quality material is available and worthy for precision cutting, there is a great emphasis on getting the most ideally cut diamond.

Precision cutting creates top-performing diamonds. By perfecting an exacting facet pattern, this can boost contrast, light dispersion, scintillations and the overall brilliance in a variety of lighting conditions. The precise alignment of the diamond’s facets function like tiny mirrors within the stone, maximizing the return of all available light.

Modern technology works to measure how well all facets of a diamond align with one another. In order to achieve this preciseness in the diamond cutting process, more carat weight is expended. From rough material to polished diamond - all costs are determined from the carat weight of the stone. Retention of weight has always been of paramount concern to the jewelry industry in the diamond cutting process. The ability to create purer rough diamond material in a lab than what is available naturally from the Earth has made larger finished stones of high quality more accessible.

Recent posts

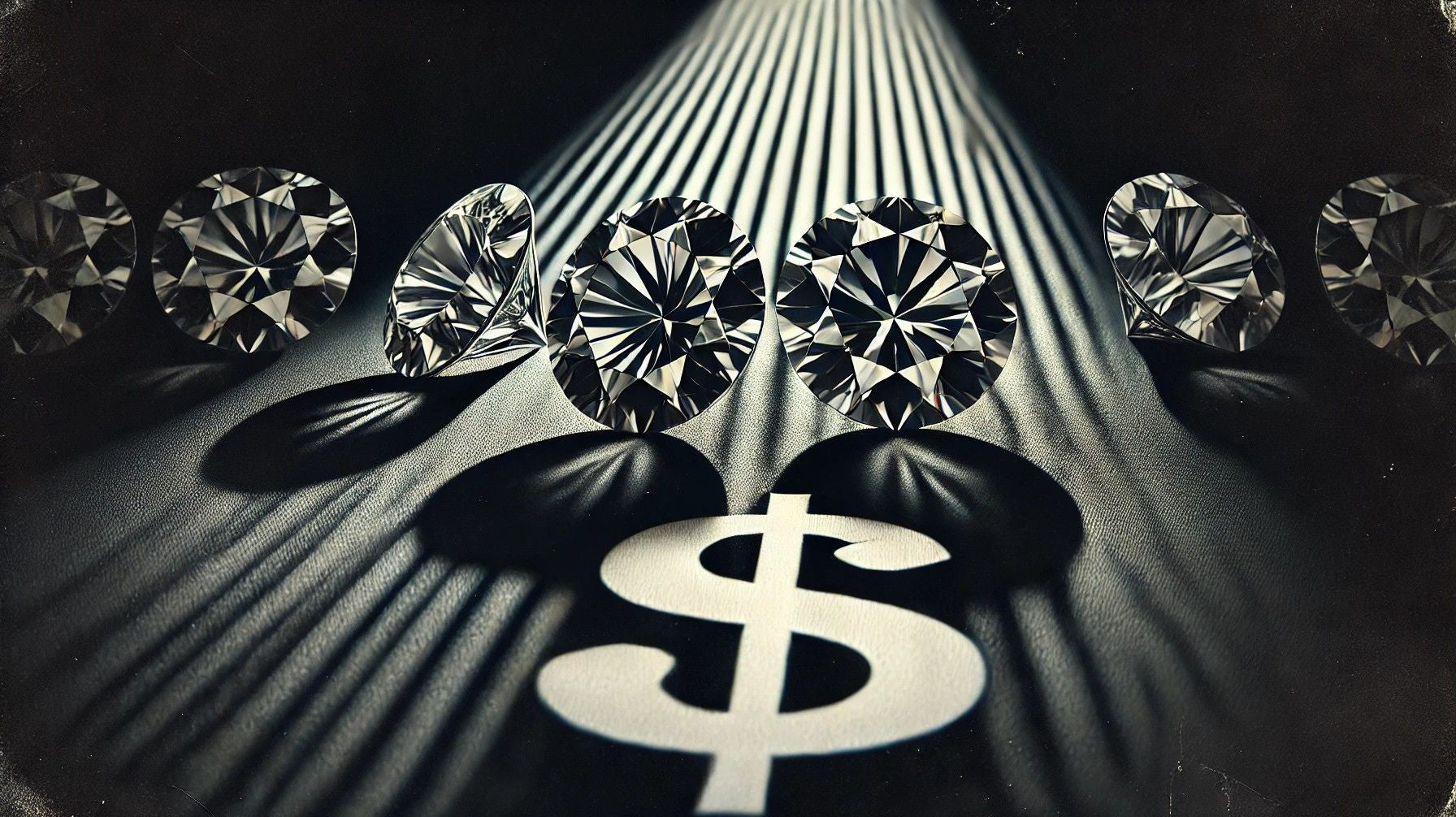

Why Diamonds Are a Smart Investment

While traditional investment options like stocks, bonds, and real estate fluctuate with market trends, diamonds hold a distinct position as a tangible, portable, and enduring store of wealth.

The Smart Investment: Rising Gold Prices vs. Platinum Value

Gold has long been a symbol of luxury, but its soaring prices have changed the jewelry market landscape. With gold costs on the rise, the price difference between gold and platinum is shrinking. This shift means that for only a slightly higher investment you can enjoy the many advantages that platinum offers over gold.

Zendaya’s Engagement Ring: A Modern Twist on the Button Back Setting

Zendaya’s engagement ring, unveiled at the 2025 Golden Globes, has quickly become the talk of the town, blending timeless vintage charm with a contemporary twist. Designed by London-based jeweler Jessica McCormack, the ring features a stunning 5.02-carat cushion-cut diamond set in a unique east-west orientation. But what truly sets this piece apart is its vintage-inspired "button back" setting, which has roots dating back to the Georgian era.